When constructing a fence, you must take select concrete adeptly – inadequately chosen cement can put your fence in jeopardy. Of primary importance when picking concrete for fence posts is compressive strength – this is a representation of the amount of force the concrete can withstand prior to crumbling. Compressive strength of concrete is quantified in pounds per square inch (PSI). A higher PSI denotes a tougher material.

When considering a fence post, an impressive strength rating of between 2,500 – 3,000 PSI should generally be sufficient. That being said, larger loads may require a more robust concrete option. Furthermore, be sure to consider the weight of the cement mixture – although lighter cement is easier to manage, it may not be sufficient to support bigger pressures. If you remain unsure as to what type of cement is most suitable for your project, it may be best to consult a professional for advice.

Achieving the perfect concrete-encased posts for your fence requires a few critical advance preparations. To start, dig a hole that is no less than two feet in depth and slightly larger in diameter than the post you intend to place within. This allowance is to make sure there is sufficient room for the concrete to expand as it sets. Moreover, if you are working with wooden posts, don’t forget to layer the base of the hole with a few inches of gravel for the purpose of efficient drainage.

With the hole prepped, you are now ready to incorporate concrete. For smaller projects, you can simply mix the concrete manually. However, if you are working on a bigger task then it would be wise to rent a mixer. To begin mixing, add the water first, then bit by bit add the dry concrete mix. The mixture’s texture should reflect that of pancake batter, but if it is too thick then adding more water is the answer. Alternatively, if it’s too thin then additional concrete mix is the key to remedying the situation.

Once the concrete is stirred up, the task of filling the depressions can begin. If you are using a concrete mixer, then emptying the mix into the hole should be an easy job. For those of you mixing by hand, you’ll need a container to transfer the concrete from the mixing bowl into the pit. Continue to fill up until it’s two-thirds full and then use a broom handle or piece of rebar to pack down the concrete. This will take out any pockets of air that may have formed.

When the excavation of the hole is complete, you can start setting up the fence post. For wooden posts, just settle them firmly into position in the cavity, making sure they sit evenly. For metal posts, use a post hole digger to form a gap that matches the size of the post. Once it’s in place, cover the hole with concrete to finish the job—following the same steps as before.

To ensure your fence post is fortified against the elements, cap the top with a protective layer. Provide it with a full day to two of curing before attaching the panels, and then you can be certain your fence post is ready for many years of sturdy service.

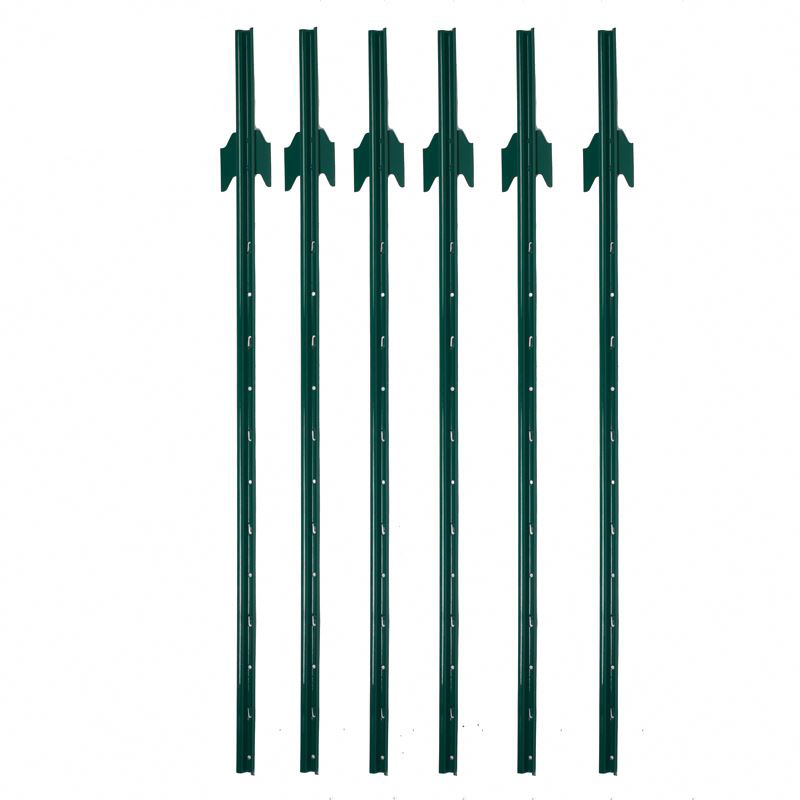

Related Product

U Post

Heavy Duty Garden U Shaped Steel Fence Post With Spade Shape: U shape, with or without spade Material: low carbon steel, rail steel, etc. Surface: Powder coated Advantage: Easily A […]

Y Post Cap

Y Posts Caps is also called safety cap or Star picket caps. It used for Y star picket . It can cover sharp edges of Y posts. Type Size(L x W X H) Thickness Weight Round 57x57x60mm […]

Y Post

Length:1.35m,1.5m,1.65m,1.8m,2.4m etc Weight:1.58kgs,1.86kgs,1.9kgs,2.04kgs/m etc Surface:painted, Hot dip galvanized, No paint Usage:farm fencing,garden fencing Packing:400pcs/pal […]

Israel Y Post

Y post with teeth provides the most reliable way of fencing wire attachment by threading the wire through the holds along the post, gripping the wire with is specially designed tee […]

Nail Stake

Product information: Description Unit Pallet Weight(kg) 3/4″x12″ 10pcs/box 150boxes/pallet 0.6200 3/4″x18″ 10pcs/box 100boxes/pallet 0.9250 3/4″x24 […]

Studded T Post

material: rail steel weight: 0.85,0.95,1.25,1.33lbs/ft etc length: 5′-10′ etc surface: painted with spade,painted no spade,unpainted with spade,unpainted without spade,hot-dipped g […]

T Post

Material: rail steel Weight: 0.85,0.95,1.25,1.33lbs/ft etc Length: 5′-10′ etc Surface: painted with spade,painted no spade,unpainted with spade,unpainted without spade,hot-dipped g […]

T Post Clip

These heavy duty T-post clips fit standard size 1.25 and 1.33 lb. studded T-posts. Manufactured from 11-1/2 gauge wire that is Hot-dipped galvanized, these clips are designed for f […]

Post time: 2023-06-20